Leveraging Biochar Machines for Carbon Credits and Storage Solutions

In the global pursuit of mitigating climate change and achieving sustainability, innovative solutions are key. Enter the biochar machine—a revolutionary technology that not only addresses waste management but also holds immense potential in the realms of carbon credits and carbon storage. This post delves into the profound impact of biochar machine on carbon credits and storage, shedding light on their role in shaping a greener future.

Biochar Machines: Beyond Waste Management

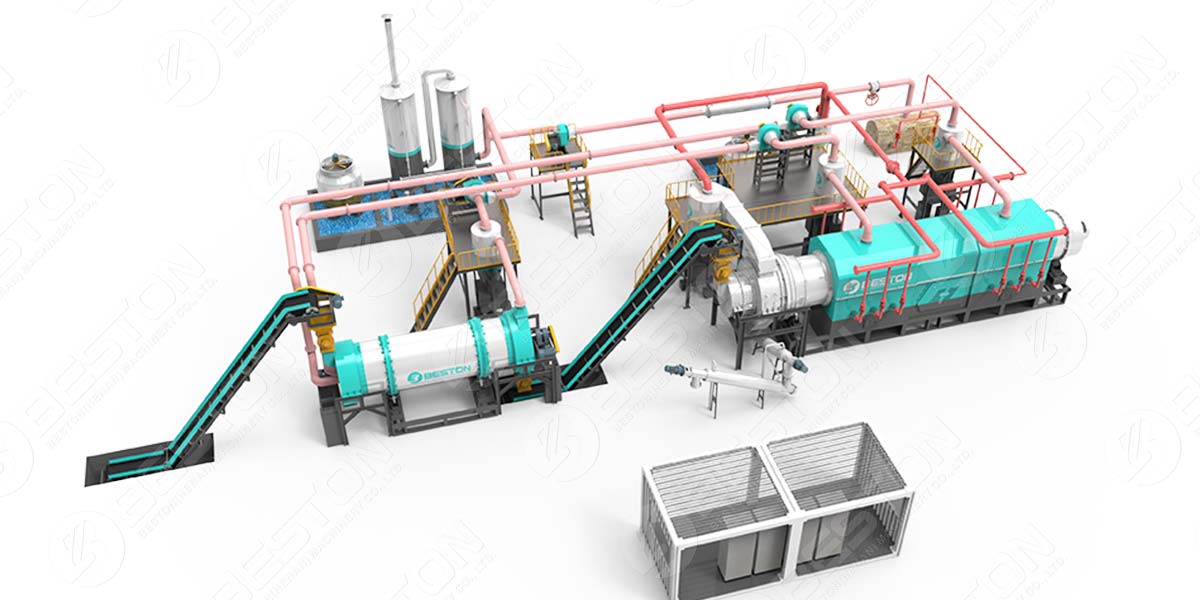

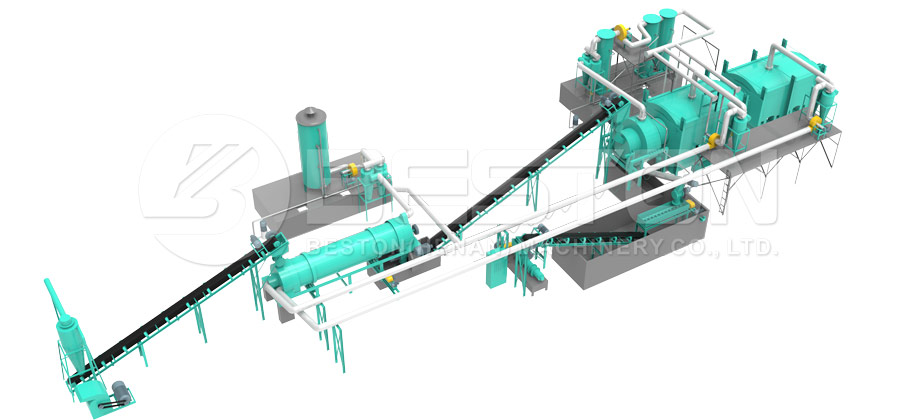

Biochar machines, often associated with converting organic waste into valuable biochar, offer a multidimensional approach to environmental challenges. While waste reduction remains a primary goal, these machines extend their impact to the intricate world of carbon credits and carbon storage.

Carbon Credits and Biochar: A Dynamic Duo

Carbon Sequestration: Biochar, a porous and stable form of carbon, can sequester carbon dioxide from the atmosphere for centuries when added to soil. This natural process of carbon capture plays a pivotal role in curbing greenhouse gas emissions.

Earning Carbon Credits: The carbon sequestration potential of biochar leads to the generation of carbon credits—financial incentives awarded for reducing carbon emissions. Farmers and industries can earn these credits by incorporating biochar into their practices.

Benefits Beyond Carbon Credits

Soil Enrichment: Biochar’s introduction to soil enhances its fertility, water retention, and nutrient absorption. This not only improves crop yields but also contributes to healthier ecosystems and sustainable agriculture.

Waste Diversion: By utilizing organic waste to create biochar by biochar reactor for sale, these machines divert waste from landfills and prevent harmful emissions that contribute to climate change.

Renewable Energy Generation: The process of producing biochar can also yield bio-oil and syngas, which have energy applications, contributing to renewable energy sources.

Towards a Greener Horizon

The role of biochar machines in carbon credits and carbon storage aligns seamlessly with the global pursuit of carbon neutrality and climate action. By utilizing biochar’s carbon sequestration properties, we not only address the challenge of excess carbon dioxide in the atmosphere but also establish a valuable pathway towards sustainability.

Investing in a Sustainable Future

The integration of biochar machines into various industries opens doors to carbon credit generation, supporting environmentally conscious practices. Industries can earn carbon credits while simultaneously fostering soil health and contributing to carbon reduction goals.

Shaping Tomorrow’s Landscape

In the intricate tapestry of carbon credits, carbon storage, and environmental conservation, biochar machines stand as catalysts for change. They remind us that innovative solutions are our allies in the battle against climate change and the pursuit of a greener, more balanced future.

As we navigate the complexities of carbon credits and carbon storage, charcoal making machine for sale emerge as tools of transformation. Their ability to convert waste into a resource that offsets carbon emissions represents a tangible pathway towards a world that values sustainability, conservation, and responsible resource utilization. Through the amalgamation of technology and ecological responsibility, biochar machines carve a path towards a brighter, more sustainable tomorrow.