How To Save Money When Obtaining A Tyre To Oil Plant

Converting a rubber tyre into fuel that can be sold is becoming more common. With each passing year, companies are developing pyrolysis machines and plants that can do this type of conversion in a minimal amount of time. Technology has increased to the point where millions of rubber tyres can be converted in this manner. The byproduct of this process is charcoal, as well as burnable liquid fuels, that can be sold to people looking for these products. If you would like to invest in one, or if you need another one for your business, this is how you can get a tyre to oil plant at the lowest possible price.

How These Plants Convert Tyres To Oil

Pryor to processing the rubber tyres, they need to be broken down into smaller pieces. There will be some type of device that can easily cut through the rubber, creating millions of pieces that can be put into the pyrolysis reactor. The next stage is activating the reactor. This requires the extraction of all oxygen within the unit. Subsequently, the unit will be turned on, allowing the temperatures inside to rise several hundred degrees, which is how the rubber is converted into oil. Click here to know more: https://bestonpyrolysisplant.com/.

What Are The Exact Byproducts That Are Created?

The tyres will produce a couple different products. The most common is charcoal. There will also be liquid burnable fuels such as bio oil that can be sold to different businesses. This could be a cosmetic company that is looking for recycled oil-based products. In most cases, however, this oil can be used in machinery. This is where you will likely sell most of it. If you do have access to millions of rubber tyres, this business could be extremely profitable.

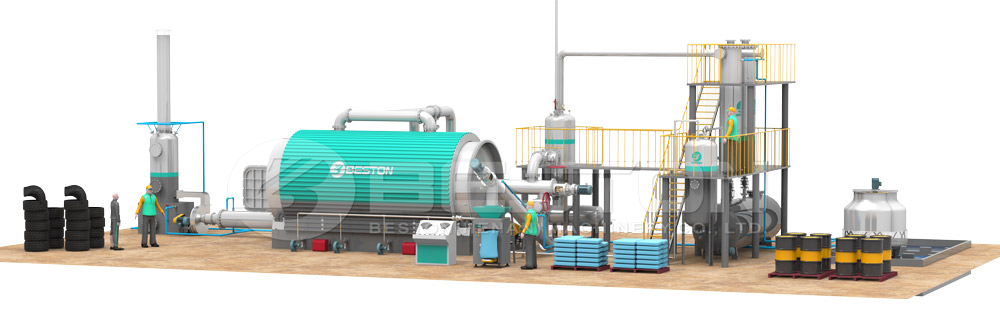

Purchasing tire pyrolysis plant is not difficult to do, but it needs to be done the right way. Instead of looking for the lowest possible price for one of them, you must first consider how they operate. They will all come with similar components including the chipper, pyrolysis reactor, and storage tanks for the charcoal and biofuel. There should also be a conveyor system that will put the material in and will also help deposit the finished products where they can be prepared for sale. Once you have evaluated each aspect of these machines, you can then ask for a quote. These estimates will show you which ones are the most inexpensive, some of which will have exceptional features and benefits.

What To Look For When You Are Purchasing One

A couple of the factors to consider will include what the hourly feeding capacity is. Some of these are capable of processing as much as 3 tons of material per hour. This has to do with the reactor size, and you should also know if you can use other materials with each unit. You may have access to municipal solid waste, biomass, and industrial sludge that can be used for this same purpose. Ask about the total power consumption, heating materials, and how much room it will take up. Once you have all of this information, combined with the low price, you can easily make the right decision.

All of this information is so helpful in making a logical choice on purchasing a tyre to oil plant. In no time, you will have your ship to you so that you can start generating revenue by processing rubber tyres. Visit the site: https://bestonpyrolysisplant.com/waste-tyre-recycling-plant-price/.