The Top Reasons To Buy An Egg Carton Machine

Have you ever thought about making egg cartons for a living? Even though it may sound like a strange idea for a business, it actually can be quite profitable. As an added bonus, it is also an eco-friendly business, meaning that you can feel good about what you do.

Years ago, egg cartons were made out of Styrofoam. Today, however, the vast majority of them are made out of recycled paper pulp. When you walk through the egg section at any grocery store, you usually will see eggs in grayish-colored cartons that were molded out of recycled paper.

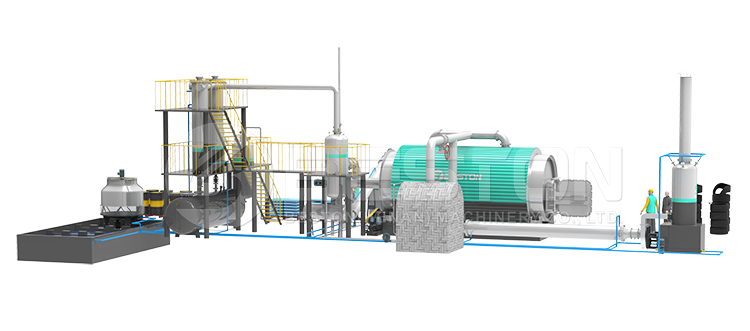

These cartons are made using special egg carton machine that mold the pulp into the shape of a carton. There are a lot of great reasons to buy an egg carton machine including the ones listed below:

1. Egg tray machines are affordable. You don’t need a lot of startup capital to buy an egg tray machine. That means that you can get your business up and running without needing to invest a ton of money. You can get started with a small, manually operated machine. As your business grows, you can upgrade to an automated machine or you can add additional machines to increase your output. When you are just starting out, however, you don’t need a ton of money.

2. Making egg cartons is an eco-friendly business. With the threat of climate change looming, recycling is more important than ever. Being able to use discarded paper to make something new helps keep more trees from getting cut down. When discarded paper finds its way into the landfill, it gives off methane gas, which contributes to global warming. Keeping the paper out of the landfill and recycling it instead helps counteract this problem. When you own a business that makes products out of recycled paper, you can feel really good about doing your part to protect the environment. Click here to know more: https://eggtraymakingmachine.net/raw-materials-egg-trays-egg-cartons/.

3. You can make more than just egg cartons. Most egg trays have interchangeable molds. That means that you can make other items out of recycled paper along with egg cartons. For instance, you might be able to make molded paper packing materials, food containers, or fruit trays. With so many options available, you can develop multiple income streams, making it easier to earn a profit with your business.

4. The raw materials are free or inexpensive. You can often get the paper that you use to make the egg cartons for free. Even if you have to buy it, it usually doesn’t cost very much. Compared to a lot of other manufacturing businesses, the material costs involved in making egg cartons are extremely low. The paper egg tray making machine is worthy of investing.

There are a lot of great reasons to buy an egg carton machine. If you are looking for an affordable, eco-friendly business that has the potential to earn a lot of profit, you should consider investing in one of these machines. They are inexpensive to buy and easy to operate. More than that, however, they also allow you to do your part to protect the planet by reusing paper that would have otherwise been thrown away.