Pyrolysis Plant – Depend on Green Technology For Processing Tyres

The pyrolysis plant typically comes in two classifications: the continuous and the batch pyrolysis plant. As the name suggests, the batch type uses a batch to feed the raw materials into the pyrolysis plant. But you should never expect the machine to feed the raw materials and discharge them simultaneously. The next process can only start after cooling down the equipment and releasing the carbon black.

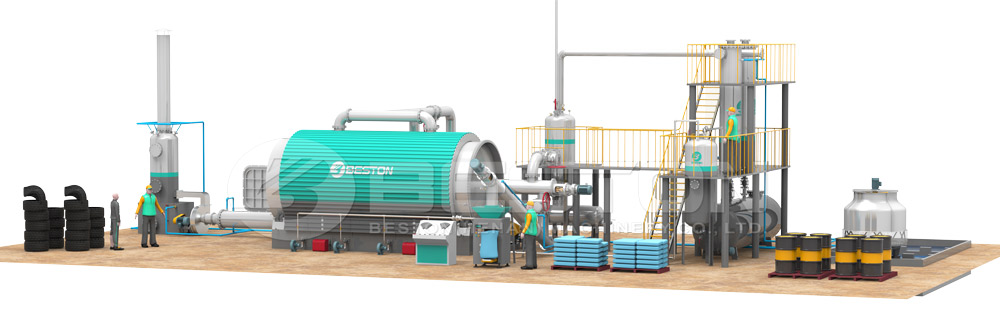

On the other hand, the continuous pyrolysis plant applies a different approach. With this type, the feeding of materials happens on one specific side. In general, these raw materials may consist of tire and plastic. When it comes to discharging, the final product is carbon black and is continuously discharged from the other side of the equipment. Both of these types of pyrolysis plants depend on green technology for pyrolysis, and this ensures an environmentally friendly process. If you are considering tire recycling, this is undoubtedly the ideal tire management solution.

Reasons to Invest in a Pyrolysis Plant

There has been a demand increase for the pyrolysis plant, and there are generally two reasons behind this. First, you get the chance to recycle or eliminate waste. Secondly, you get an opportunity to make money while doing so. Due to the advancement in social modernization, there has also been growth in the rubber industry. Besides, rubber products have a variety of applications, especially when it comes to tire manufacture. Lots and lots of scrap materials, such as tires, are created and accumulated to such huge amounts. Over time, because of the erode-resistant property of tires, hygiene, and the environment posed the highest pollution risk. Get a reliable pyrolysis plant manufacturer here.

What’s even more intriguing about investing in this pyrolysis plant is that, after processing the raw materials, your different types of waste tires can undergo pyrolysis and create useful resources. What’s more, these resources can be useful in various areas:

– Tire oil. Not only can you sell this product, but you can also use it as reactor fuel. Furthermore, when you add tire oil into an oil generator, it will generate electricity.

– Combustible gas. This can be stored for later use as heating fuel. It can also be returned to the furnace for heating the reactor.

– Steel wire. Apart from selling this product, you can deeply process it to create steel bloom.

How Does the Pyrolysis Plant Work?

Typically, this tyre recycling machine for sale decomposes your raw materials in a very high-temperature process until it creates a varsity of useful resources. As you can see, it’s quite intriguing that this pyrolysis plant can create renewable resources out of waste and pollution.

For the batch pyrolysis plant, raw materials of about 120mm will be suitable. That means that you should use pretreatment devices to process relatively large tires. However, for continuous operation in a fully automatic pyrolysis plant, you should scrap the materials to a size of 30-50mm. There are specific pretreatment devices, however, that are perfect to process the whole tire.

Investing in such equipment or project will produce significant profit for both the society and the economy. Get one today! Obtain more information on the oil sludge pyrolysis plant.