A Sustainable Approach to Energy Fuel Production from Biomass

In the quest for sustainable energy sources, biochar has emerged as a promising candidate. Biochar, a charcoal-like substance produced from biomass, not only holds potential as a soil amendment but also as a source of renewable energy fuel. This article delves into the process of biochar production from biomass by biochar making machine and explores its role in the generation of energy fuel, emphasizing its environmental benefits and technological advancements.

Understanding Biochar and Biomass

Before delving into biochar production, it’s essential to grasp the fundamentals of biochar and biomass. Biomass refers to organic materials derived from plants and animals, including wood chips, agricultural residues, and organic waste. These materials possess carbon compounds essential for biochar production.

Biochar, on the other hand, is a stable carbon-rich product obtained through the process of mobile biochar unit, which involves heating biomass in the absence of oxygen. This process results in the decomposition of organic matter into biochar, bio-oil, and syngas. Biochar distinguishes itself from conventional charcoal due to its porous structure, high carbon content, and ability to sequester carbon in the soil for extended periods.

Biochar Production Process

The production of biochar involves several stages, each contributing to its quality and properties:

Feedstock Preparation: The biomass feedstock undergoes preprocessing, including chipping, shredding, or grinding, to ensure uniform size and facilitate efficient pyrolysis.

Pyrolysis: The prepared biomass is subjected to pyrolysis in a controlled environment with limited oxygen. This process typically occurs in a pyrolysis reactor or kiln, where the biomass is heated to temperatures ranging from 350°C to 700°C. The absence of oxygen prevents combustion, leading to the thermal decomposition of biomass into biochar, bio-oil, and syngas.

Cooling and Collection: The resulting biochar, bio-oil, and syngas undergo cooling and condensation to separate the products. Biochar, with its stable carbon structure, is collected for further processing and utilization.

Activation (Optional): Some biochar production processes include an activation step to enhance its porosity and surface area. Activation involves subjecting biochar to high temperatures in the presence of activating agents like steam or carbon dioxide.

Energy Fuel Production from Biochar

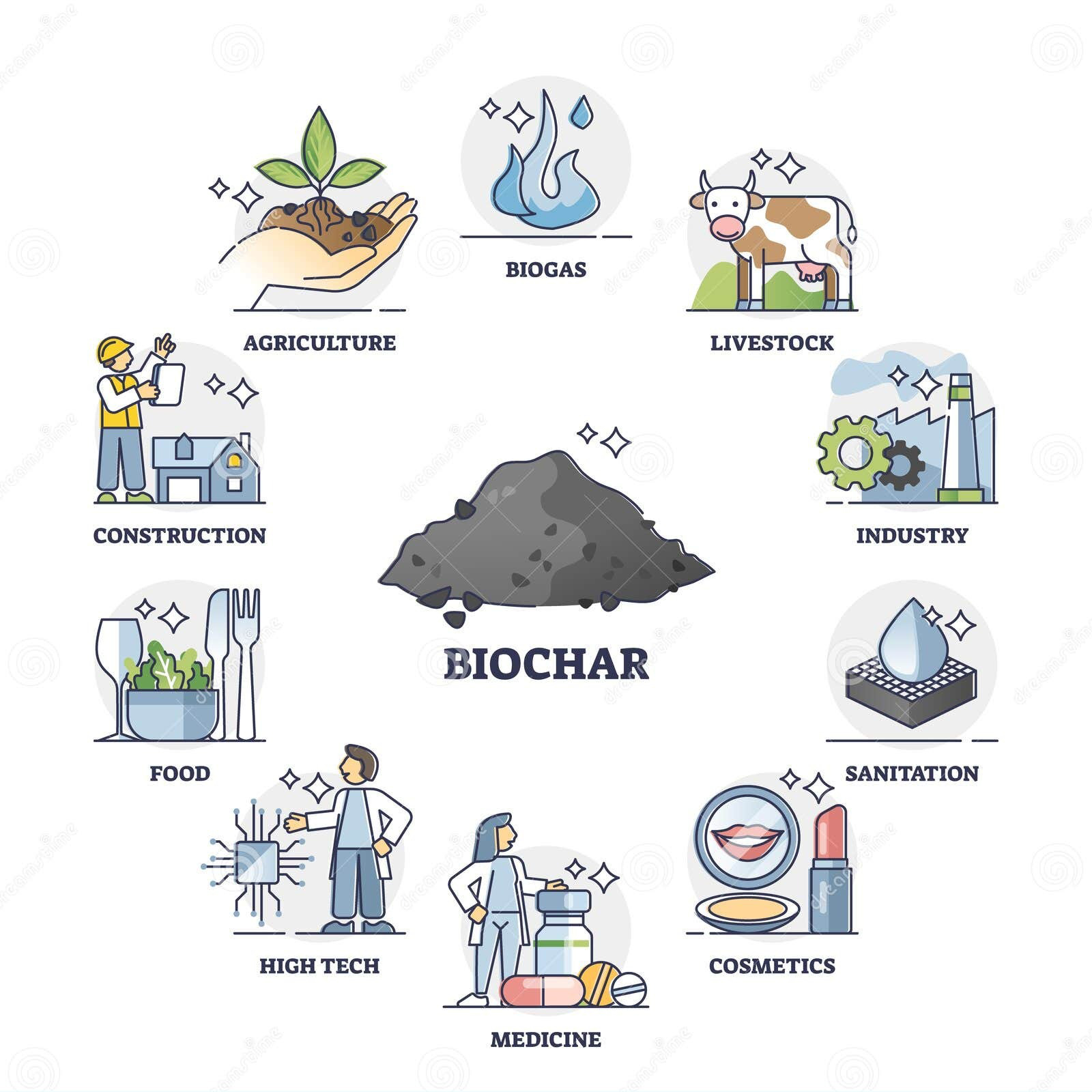

While biochar is primarily recognized for its soil amendment properties, recent advancements have explored its potential as an energy fuel. The following are key pathways for utilizing biochar in energy production:

Combustion: Biochar can be directly combusted to generate heat energy. In this process, biochar serves as a renewable fuel source, similar to traditional charcoal, but with the added advantage of being produced from sustainable biomass feedstock. Combustion of biochar releases heat energy, which can be utilized for various applications, including residential heating, industrial processes, and electricity generation through steam turbines.

Gasification: Gasification involves converting biochar into syngas, a mixture of carbon monoxide, hydrogen, and methane, through a thermochemical process. Syngas can be used as a clean fuel for power generation or further processed into liquid fuels such as ethanol or synthetic diesel. Gasification offers higher energy efficiency compared to direct combustion and enables the utilization of biochar-derived syngas in combined heat and power (CHP) systems.

Co-firing: Co-firing involves blending biochar with conventional fuels such as coal during combustion in power plants. This approach reduces the carbon footprint of energy generation by utilizing renewable biochar alongside fossil fuels. Co-firing biochar with coal can also improve combustion efficiency, reduce emissions of greenhouse gases and air pollutants, and prolong the lifespan of combustion equipment by mitigating corrosion and fouling.

Environmental Benefits of Biochar Energy Fuel

The utilization of biochar for energy fuel production offers several environmental benefits, including:

Carbon Sequestration: Biochar sequesters carbon in a stable form, preventing its release into the atmosphere as carbon dioxide. By converting biomass into biochar produced by wood chips charcoal making machine, carbon is effectively removed from the carbon cycle, contributing to climate change mitigation efforts.

Waste Management: Biochar production provides a sustainable solution for managing organic waste and agricultural residues. By converting biomass into biochar, organic materials that would otherwise decompose and release methane—a potent greenhouse gas—are utilized beneficially.

Soil Health Improvement: While not directly related to energy fuel production, the incorporation of biochar into soil enhances soil fertility, water retention, and nutrient availability. This soil amendment property of biochar promotes sustainable agriculture practices and contributes to ecosystem resilience.

Technological Advancements in Biochar Production

Recent advancements in biochar production technologies have enhanced efficiency, scalability, and versatility, making biochar-based energy fuel production economically viable and environmentally sustainable. Some notable technological developments include:

Continuous Pyrolysis Systems: Continuous pyrolysis systems enable uninterrupted biochar production, reducing energy consumption and improving process efficiency. These systems utilize innovative reactor designs and process automation to optimize pyrolysis conditions and maximize product yield.

Integration with Renewable Energy Systems: Biochar production facilities are increasingly integrated with renewable energy systems such as solar, wind, or biomass power plants. This integration allows for synergistic energy production, where excess heat or electricity generated from renewable sources is utilized for biochar production, improving overall energy efficiency and reducing operating costs.

Co-production of Value-added Products: Advanced biochar production processes facilitate the co-production of value-added products such as bio-oil, syngas, and specialty chemicals. These products diversify revenue streams and enhance the economic viability of biochar production, making it an attractive investment for industries seeking sustainable energy solutions.

Conclusion

Biochar production from biomass offers a sustainable approach to energy fuel production with significant environmental benefits. By harnessing biochar as a renewable energy resource, we can mitigate climate change, manage organic waste, improve soil health, and promote sustainable development. With continued technological advancements and policy support, biochar-based energy fuel production has the potential to play a vital role in the transition to a low-carbon economy, contributing to global efforts to combat climate change and ensure energy security for future generations. View more information from Beston Group Co., Ltd..