Charcoal Making Method – Pyrolysis

Charcoal, an ancient substance with a myriad of modern applications, has been utilized by humanity for centuries. One of the most intriguing methods of producing this versatile material is through pyrolysis. In this comprehensive exploration, we will delve into the intricate world of charcoal maker machine, examining the processes, techniques, and the science behind the art.

The Origins and Evolution of Charcoal Making

Charcoal making has deep historical roots, dating back to ancient civilizations. From the simple earth mound kilns of early human societies to the advanced pyrolysis methods employed today, the evolution of charcoal production is a testament to human ingenuity. Understanding the historical context provides a foundation for appreciating the advancements in pyrolysis technology.

The Fundamentals of Pyrolysis

Pyrolysis, derived from the Greek words “pyro” (fire) and “lysis” (separation), is the process of decomposing organic materials in the absence of oxygen. This fundamental concept forms the core of charcoal production through the controlled heating of biomass. This section will explore the science behind pyrolysis, detailing the chemical reactions that transform organic matter into charcoal. Beston charcoal making machine price is competitive. Get a consultation from this expert.

Biomass Selection and Preparation

The quality of charcoal is deeply influenced by the choice of biomass. Different materials, from wood to agricultural residues, impart distinct characteristics to the final product. This section will guide readers through the selection and preparation of biomass, discussing the impact of moisture content, size, and type on the pyrolysis process.

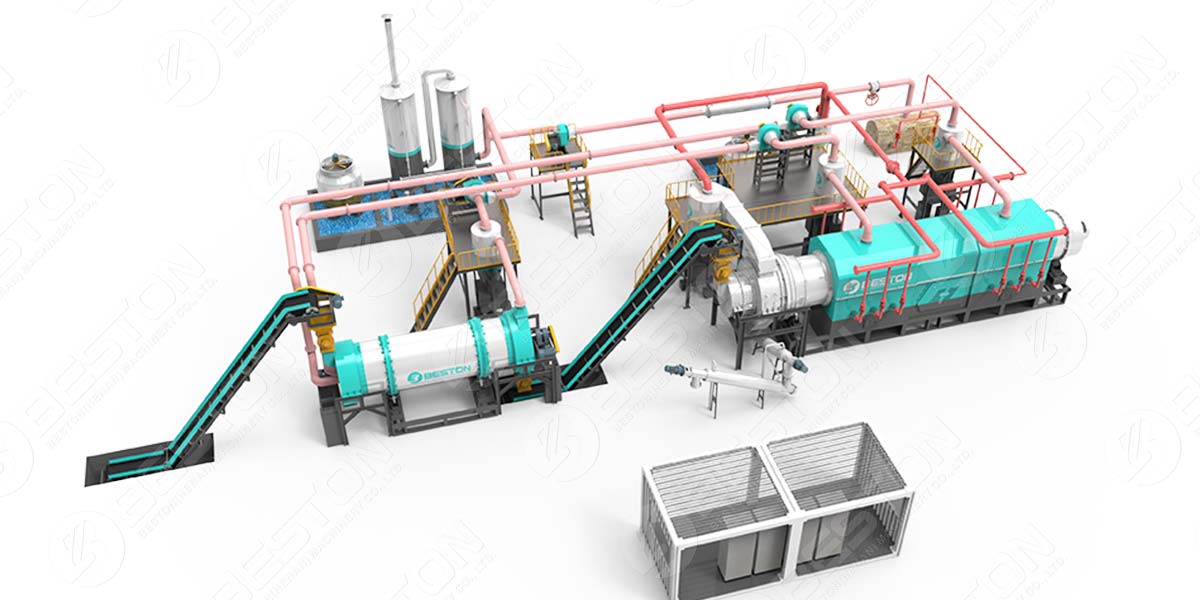

Pyrolysis Reactors and Equipment

Modern charcoal production relies on a variety of reactors and equipment designed to control temperature, airflow, and residence time. From traditional kilns to advanced retort systems, understanding the different types of pyrolysis reactors is essential for optimizing charcoal yield and quality. This section will provide an in-depth analysis of the various equipment used in pyrolysis.

The Pyrolysis Process in Action

With the groundwork laid, it’s time to witness the pyrolysis process in action. We will walk through the stages of heating, decomposition, and cooling, exploring the intricacies of each phase. Special emphasis will be placed on the importance of temperature control and the role of volatile byproducts in the formation of high-quality charcoal.

Quality Control and Charcoal Characterization

Producing premium charcoal requires rigorous quality control measures. This section will discuss methods for assessing charcoal quality, including carbon content, hardness, and ash content. Additionally, we will explore the potential applications of charcoal based on its unique characteristics, from cooking fuel to industrial uses.

Environmental Impact and Sustainability

As global concerns about environmental sustainability grow, evaluating the impact of bbq charcoal machine becomes crucial. This section will examine the environmental implications of pyrolysis-based charcoal making, discussing mitigation strategies, and exploring how this ancient practice can align with modern sustainability goals.

Conclusion: Embracing the Legacy of Pyrolysis in Charcoal Making

In conclusion, the art and science of charcoal making through pyrolysis unveil a rich tapestry of tradition and innovation. From its historical origins to the cutting-edge technology employed today, pyrolysis remains a cornerstone in the production of this versatile material. As we navigate the complexities of biomass selection, reactor design, and quality control, it becomes evident that the legacy of pyrolysis in charcoal making is one of enduring craftsmanship and environmental responsibility.