What Does An Average Tyre Pyrolysis Plant Cost Today?

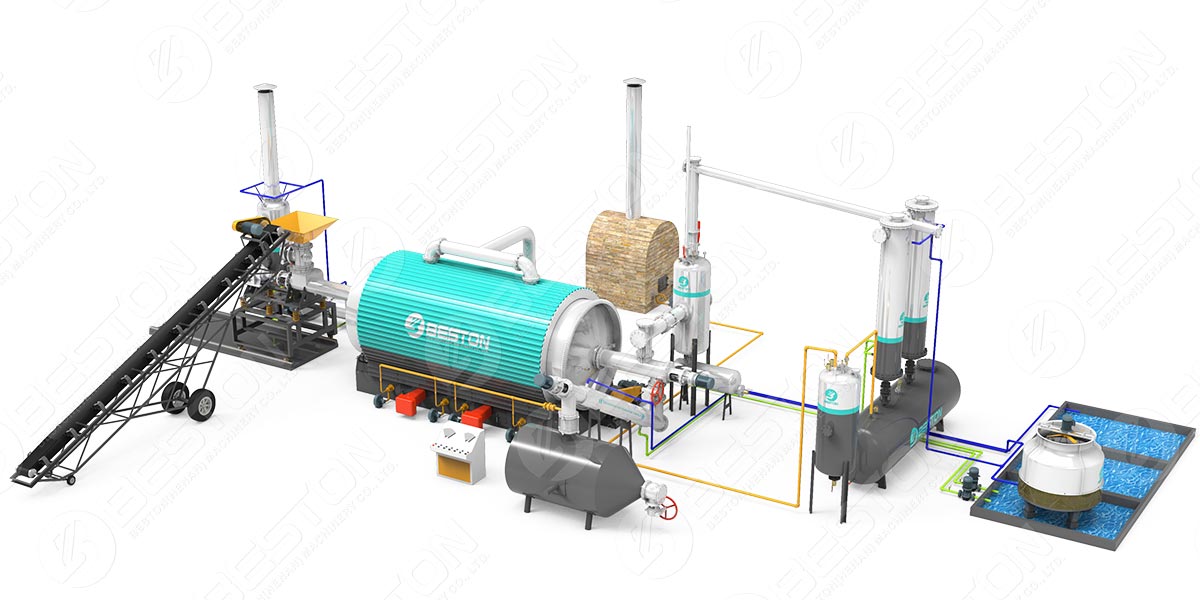

The cost of the pyrolysis plant has changed over the years. Inflation, the cost of materials, as well as the cost of labor, can pertain to how much it will be once you purchase it. It’s only going to take a few days to decide on which one will be best suited for your business. However, the cost of operating the pyrolysis plant, and obtaining, really depends on what manufacturer you are getting it from. This is what you can expect if you would like to purchase a brand-new pyrolysis plant that can convert rubber tyres into a burnable fuel.

What Do They Cost On Average?

Most of them are going to cost several thousand dollars that you can purchase from many different sources. If you need a low tyre pyrolysis plant cost, you will have to obtain them from the right manufacturer or distributor. Some of these companies are able to produce them for less, and as a result of that, sell them for a much lower price point. In some cases, these are going to outperform most of the ones that you will find today. It’s very easy to contact the manufacturers directly and get a quote on how much the exact unit you would like to pay for is today.

How To Save Money When You Buy One

If you want to save money, you will have to obtain one from a reliable company that will help you save as much money as possible. Not all of the businesses that sell them for less are producing quality tyre pyrolysis plant. In most cases, the largest businesses are the ones that will help you save the most money. If you can find a business that has been around for decades, they will likely be producing some of the best ones. Eventually, you will obtain a quote from a good company that will save you money on your purchase. It will only take a few hours to get one right away.

How Much Can You Save When You Purchase One

If you want to save as much money as possible, it must come from a business that is known for specializing in pyrolysis machines. They will probably have machines and continuous waste tyre pyrolysis plant that you can get from their business. They may also have distribution sites where you can obtain them from a nearby resource. Overall, it’s a good idea to compare as many companies as possible. This will enable you to save money and also get one of the best systems.

If you have not been able to find a reliable source for pyrolysis plants, you should start looking today for some of these businesses. It will be easy to save money and obtain one quickly. It becomes from a business that has years of experience in this industry, you can count on the quality of the waste tyre to oil plant that they will be provided to you. Now that you know how much a tyre pyrolysis plant cost will be, you can decide on which one will be the best one for you and your business.