Bio Charcoal Carbonization Furnaces To Process Agricultural Waste

Carbonization is a process that has useful applications when it comes to dealing with agricultural waste and municipal waste. The process involves heating biomass waste to high temperatures without air to produce solid porous carbon. Learning how different carbonization equipment function will help you to understand the benefits of the technology for clean fuel production and agricultural waste management.

Most people have no idea who much waste is produced by the agriculture industry on an annual basis. The reality is, however, that harvesting and processing crops leaves behind lots of biomass waste including peanut shells, sugarcane bagasse, rice hulls, straw, coconut shells, etc. While there are lots of ways to dispose of agricultural waste, not all of them are optimal. In many cases, the waste material is used as livestock feed, but unfortunately, the limited nutritional value of it means livestock feed is not the best use for the material.

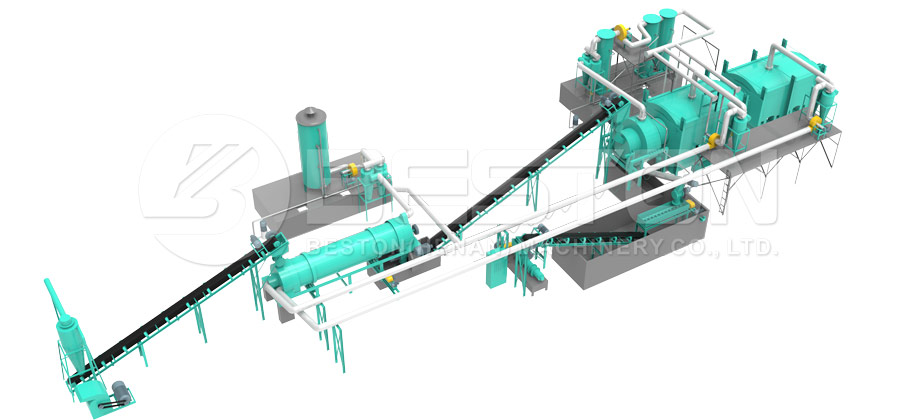

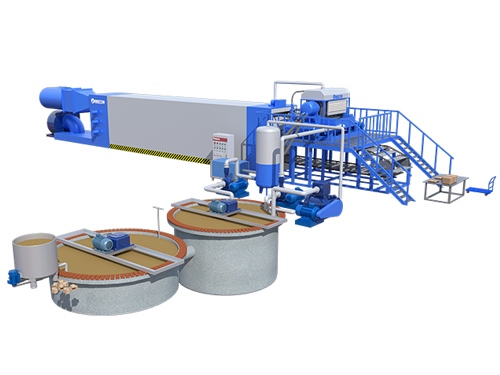

Burning unprocessed agricultural waste is arguably one of the worst methods of disposal when it comes to limiting environmental damage. Fortunately, bio charcoal carbonization furnace technology means the waste can now be converted into high-carbon biochar fuel without the emission of any atmospheric pollutants. You can find bamboo charcoal machines, coconut shell carbonization furnaces and many more different biochar making machines for sale online. All of the biochar production equipment uses carbonization processes to transform biomass waste into biochar fuel briquettes with zero pollution.

One of the great things about biochar fuel briquettes is the high carbon content ensures they produce little smoke when burnt. Consequently, the briquettes are a great fuel choice for outdoor cooking appliances. In addition to being used as fuel, biochar also makes an excellent soil additive. It has antimicrobial properties and a rich micronutrient profile, which means it can increase crop yields substantially and prevent root diseases.

When it comes to exploring how charcoal carbonization furnaces work, the process is very simple. Biomass waste is heated to extremely high temperatures in an air (oxygen)-free chamber. The absence of oxygen results in the biomass waste carbonizing into solid porous carbon as opposed to burning. Depending on the type of biomass waste fed into the carbonization machine, additional byproducts, like wood vinegar and tar, are also produced. The good news is that many of the byproducts also have value in the global commodity marketplace.

When charcoal carbonization furnaces are used to process wood chips and sawdust waste by the sawdust briquette charcoal making machine, for example, one of the byproducts is wood vinegar. Wood vinegar has many commercial applications including fertilizers and pest repellents.