Buying a Carbonizer Machine In China

Buying a new machine is hard for most people is hard because most of them don’t know what to look for and whether it is going to serve the purpose. It is important to take time and learn as much as possible about a given machine before putting in your money. The last thing you want is to realize the machine is not producing enough or it is producing way more than you need. You need to find the perfect balance to make sure you are getting what you need. When buying a carbonizer machine(hornos metálicos para hacer carbón), you need to choose the right option.

Investing in a carbonizer machine is a great way to make your own fuel. This is going to help you reduce your expenses because you can easily make your own. All you have to do is look for raw materials, which isn’t that hard. If you sit down and do the math, you will most likely be convinced to invest in a carbonized machine.

People are becoming more and more conscious about the environment. This is why they are always looking for energy-friendly options, and one of them is fuel. Instead of hurting the environment using fossil fuels, it is better to use charcoal (planta de carbonización)briquettes. To make these briquettes, you need to carbonize the materials first. You need to have the right carbonizer because it is going to determine the amount of charcoal you can make.

People are choosing this method because it makes use of raw materials that are no longer useful. Recycled materials mean less dependence on new materials which can involve things like cutting down a tree.

There is high demand for briquettes and it can end up being a commercial success. There are many who have managed to make a lot of money by selling charcoal(https://www.bestoneco.com/maquina-para-hacer-carbon-vegetal/).

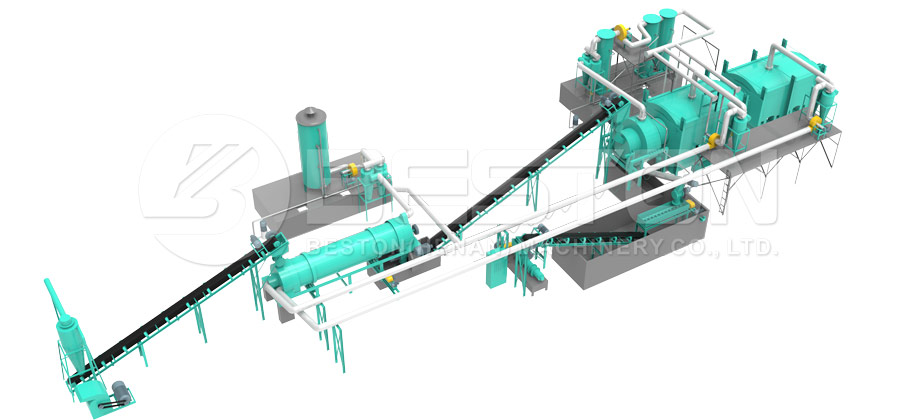

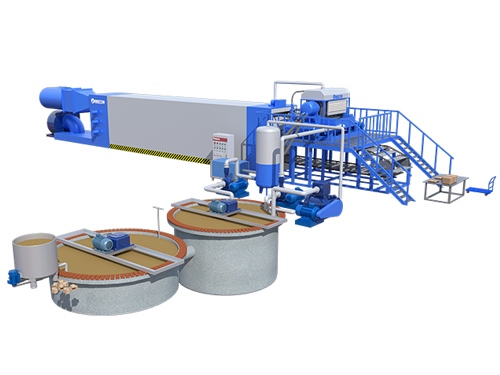

These machines are efficient and allow you to produce a lot of charcoal in a short time. You will end up with quality briquettes, and you are going to be impressed when it comes out the way you expected. The machines have been specifically designed for your situation.

There are many applications for this. There are those who use it in making activated carbon, which has large market demand. You can get a high profit by making activated carbon. The carbonization plant can also produce biomass carbon, which has higher carbon content. This is why it is profitable to use a carbonizer in making activated carbon.

There is a wide range of options to choose from when buying a carbonizer machine(Beston Group China). Take your time and choose the best option for you. See what purpose you want it to serve, then choose one that will meet your goals. There are experts who will be ready to help you out and provide you with all the important information.

A carbonizer machine is a good investment when you choose the right one. The good thing is there are different price ranges, which means you are going to get something you can afford.