Continuous Pyrolysis Plant: A Solution for Large-Scale Plastic Recycling

In the relentless pursuit of sustainable solutions to tackle the burgeoning plastic crisis, the continuous pyrolysis plant emerges as a technological beacon, promising not just recycling but a transformative approach to managing plastic waste on a large scale.

Understanding the Core Concept

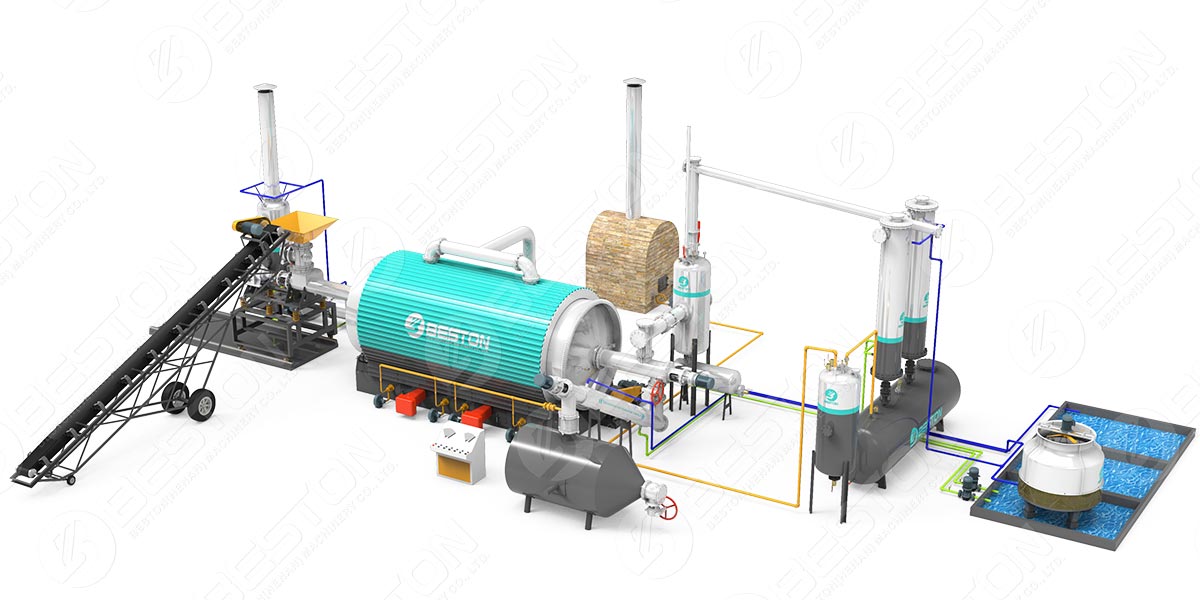

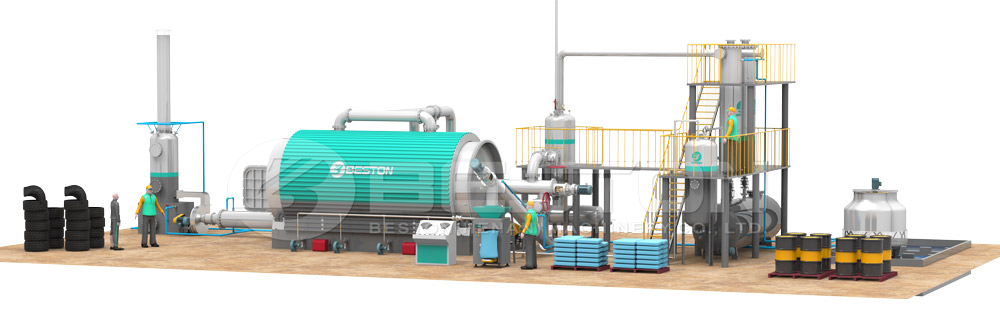

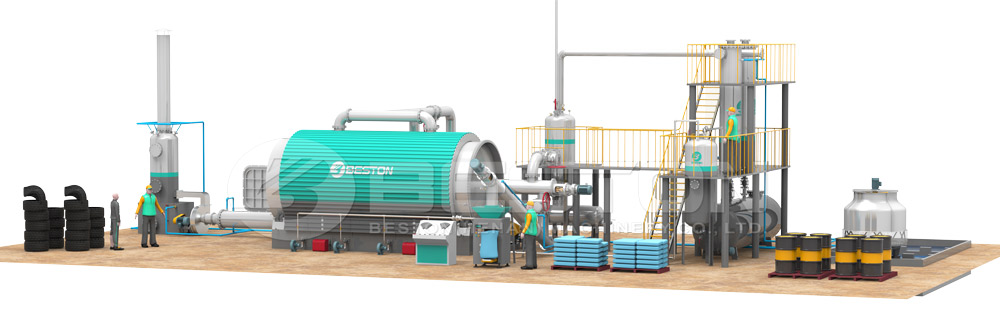

At its essence, a continuous pyrolysis plant is an advanced industrial apparatus designed to employ the principles of pyrolysis – a thermochemical decomposition process – for the conversion of plastic waste into valuable end-products. This sophisticated machinery operates in a continuous manner, distinguishing it from batch pyrolysis setups.

The intricacies of the process involve subjecting plastic materials to high temperatures in the absence of oxygen, thereby inducing a molecular breakdown. This results in the formation of a variety of products, with the most notable being pyrolysis oil, carbon black, and syngas.

Pyrolysis Oil: The Liquid Gold

One of the primary outputs of a continuous plastic pyrolysis machine is the coveted pyrolysis oil. This substance, with its versatile applications, serves as a cornerstone for a sustainable circular economy. Its composition includes a mixture of hydrocarbons derived from the thermal decomposition of plastic, presenting a potential alternative to conventional fuels.

The beauty of pyrolysis oil lies in its adaptability – it can be utilized as a fuel for industrial processes, a feedstock for chemical production, or even further refined into transportation fuels. This versatility not only enhances its economic value but positions it as a key player in mitigating the environmental impact of plastic waste.

Carbon Black: Resurrecting Resources

Simultaneously, the continuous pyrolysis plant generates carbon black, a powdery substance rich in carbon content. Rather than relegating carbon black to the realm of industrial byproducts, innovative applications have surfaced, breathing new life into this often-overlooked material.

Carbon black derived from pyrolysis boasts applications in the manufacturing of rubber, ink, and even as a reinforcement agent in the production of concrete. The utilization of this byproduct in various industries underscores the potential for creating a closed-loop system where waste transforms into valuable raw materials.

Syngas: A Gaseous Resource

Completing the triumvirate of outputs is syngas, a synthesis gas composed of hydrogen, carbon monoxide, and trace elements. While syngas finds applications in the generation of heat and electricity, its true potential lies in serving as a precursor for the synthesis of chemicals and fuels through further processing.

The ability of a continuous pyrolysis plant to yield syngas expands the horizons of resource recovery, offering a comprehensive approach to harnessing the latent energy within plastic waste. This not only aligns with sustainability goals but also presents an economically viable avenue for industries seeking cleaner alternatives.

Operational Distinctions

What sets the continuous pyrolysis plant apart from its batch counterpart is its seamless, uninterrupted operation. This continuous mode of processing plastic waste ensures a steady output of valuable products, optimizing efficiency and minimizing downtime.

The operational cycle involves a continuous feeding system, where plastic waste is introduced into the reactor without halting the overall process. This streamlined approach enhances productivity, making the continuous pyrolysis plant an ideal choice for large-scale recycling operations where a constant influx of plastic waste demands an equally continuous solution.

Environmental Implications

The adoption of continuous pyrolysis plants holds profound environmental implications. By diverting plastic waste from conventional disposal methods, these plants contribute significantly to the reduction of landfill burden. Furthermore, the conversion of plastic into valuable resources mitigates the need for extracting new raw materials, thereby curtailing the environmental footprint associated with traditional manufacturing processes.

In essence, the continuous pyrolysis plant embodies the essence of a circular economy, where waste becomes a resource, and environmental sustainability aligns with economic viability.

Technological Advancements and Future Prospects

As technology continues to evolve, the landscape of continuous pyrolysis plants is ripe for advancements. Innovations in reactor design, process optimization, and the integration of smart technologies are poised to enhance the efficiency and scalability of these recycling facilities. Beston Group Co., Ltd. has been committed to developing more efficient plastic pyrolysis technology. If you want to know more related information, please visit: https://bestonasia.com/

The future holds promise for the integration of artificial intelligence and automation in the operation of continuous pyrolysis plants, paving the way for even more precise control and resource recovery. Such technological strides not only elevate the efficacy of plastic recycling but also position these plants as cornerstones in the global effort to address the plastic crisis.

Conclusion

In the grand tapestry of waste management, the continuous pyrolysis plant stands as a beacon of innovation and sustainability. Its ability to transform plastic waste into valuable resources – pyrolysis oil, carbon black, and syngas – speaks to the potential for reshaping our approach to plastic recycling on a large scale. With operational efficiency, environmental conscientiousness, and a keen eye on technological advancements, these plants emerge not just as a solution but as a fundamental pillar in the quest for a more sustainable future.