Advantages Of High Quality Charcoal Making Plant

Did you know there are different kinds of charcoal? Are you aware of the difference in quality of different types of charcoal produced by charcoal making plant? To untrained eyes, all charcoal looks the same but there is a huge difference in terms of moisture content, energy density and overall quality of product. In this article, we will explore difference in quality of different types of charcoal and why it makes sense for you to invest in a high quality charcoal manufacturing machine to achieve consistency and higher quality.

Majority of the charcoal produced globally is used as a dense energy source. It burns clean and can be molded into a variety of shapes to fit a huge range of products. However, charcoal is also increasingly being used in many other industries including the food industry, beauty industry, pharmaceutical industry as well as in various other industries in different forms. Therefore, charcoal manufacturing business opens up the door for you to supply high quality charcoal to a wide range of industries but you can’t rely on the traditional process of making charcoal to consistently deliver higher quality needed in various applications.

The problem with traditional way of manufacturing charcoal is that the product quality is inconsistent and presence of moisture can significantly alter the product quality. This is why, you need to invest in a high quality charcoal manufacturing machine. A high-quality machine will ensure consistency in the quality of charcoal and this consistency will lead to happy buyers who will never reject any of the products sold by you. Happy buyers will bring more sales and can help your business grow immensely. Here is the coconut shell charcoal machine price for you to view.

Unfortunately, not all of these business owners have the necessary expertise and knowledge to manufacture high quality sawdust charcoal making machine for sale. More often than not, they use low quality materials for making machines and do not pay attention to the design which results in poor performance. However, you do get a bargain in terms of price but buying a machine that fails to deliver high performance completely defeats the purpose of investing in a machine, in the first place.

That said, you need to do your own research in order to buy a machine that delivers high performance consistently and allows you to supply high quality charcoal to buyers every time they place an order. Thankfully, there are hundreds of such suppliers, both local and foreign, that can supply durable and reliable machines for manufacturing charcoal. In order to find such suppliers, it is best to get in touch with someone who is already running a charcoal making business. Another option is to use your favorite search engine to find suppliers on various trade portals with listings of these machines. You can also go to your local trade association and find people who have been in this industry for long and you should be able to get some recommendations.

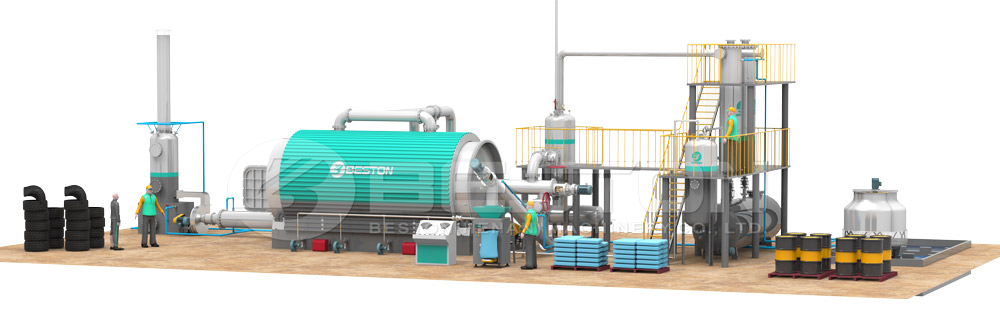

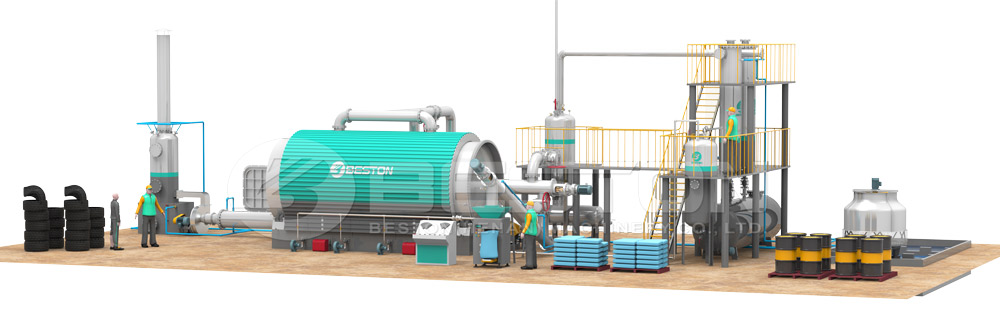

To conclude, charcoal, especially high quality charcoal, is in high demand in a variety of industries and you can take advantage of this huge demand by investing in a high quality charcoal making plant. So, keep the above mentioned tips in mind and find a supplier known for delivering high-quality machines that will keep performing consistently and allow you to take your business to the next level. Start your investment from Bestonturkey.Com/.